This discussion thread has come to a successful conclusion as indicated by the following image:

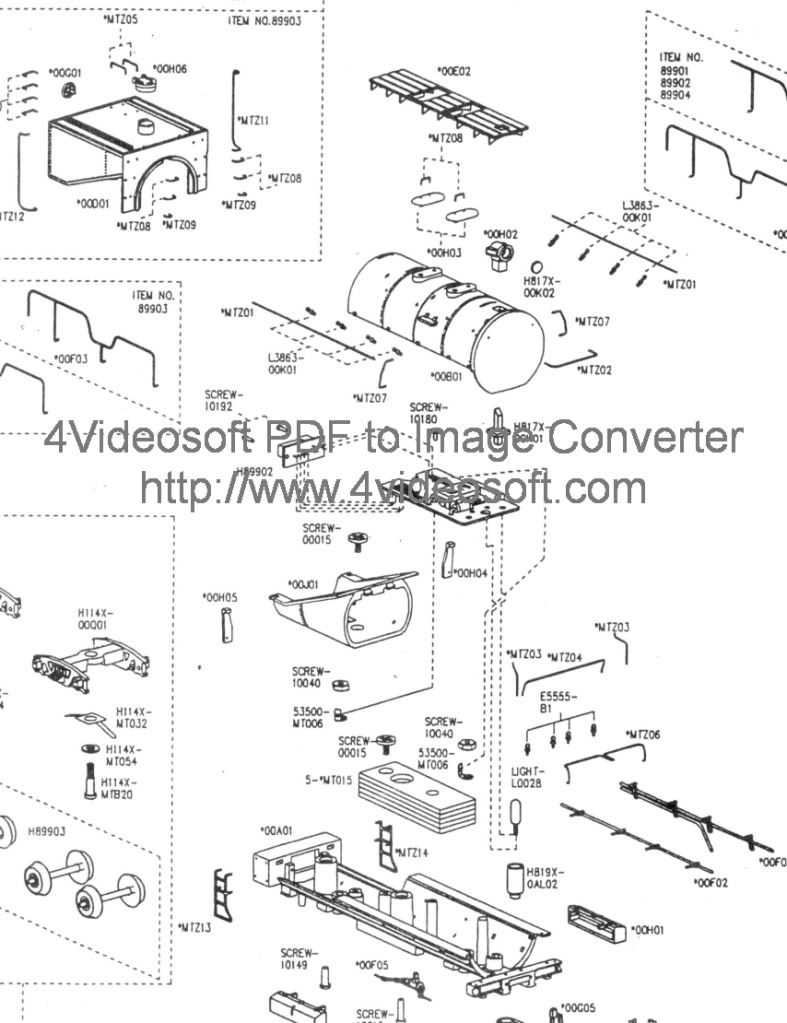

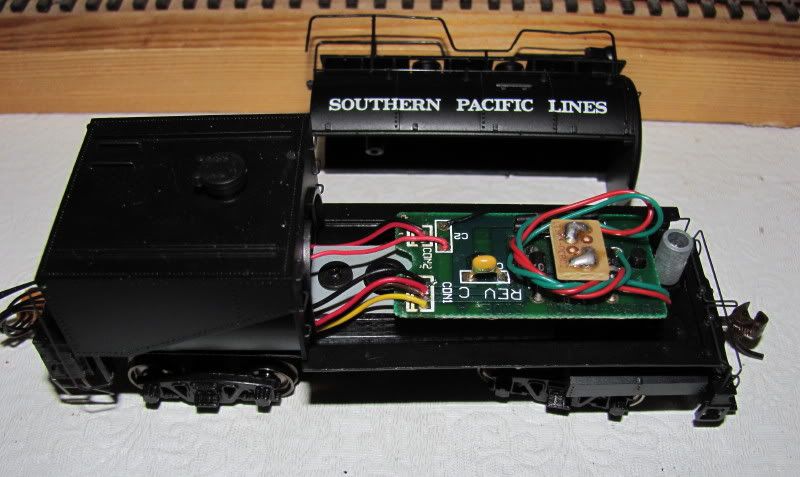

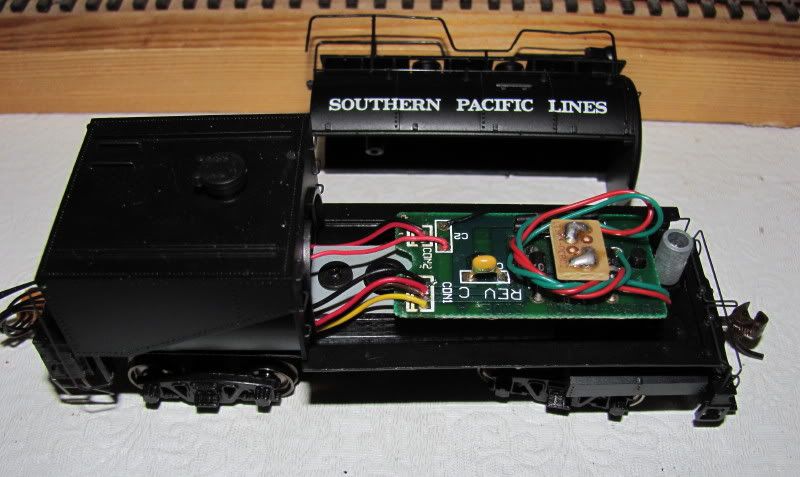

Close examination of the disassembled components reveal that the upper tank had been GLUED to the chassis where the back of the tank meets the chassis.

For those wishing to follow in my steps, I leave the following guidelines and cautions:

1) I used a hobby knife to gain the release of the stubborn upper tank section. I had initially attempted to pry under the side viewed in the picture, but release did not come until I had pried on the opposite side under the rear and middle sections of the tank. It released with a start causing me concern that the knife may have done damage to the circuit board or wiring (which is possible). Note the lip on the removed upper tank: use care to get the knife under this lip.

2) While loose, several more steps are necessary in order to free the upper tank. The upper handrails need to be separated from the front of the tender. I was able to remove one by hand, but the second one required the use of light needle nose pliers. While holding the upper tank nearly in its original position, it is necessary to back the tank away from the front section in order to free a tongue that secures that connection. I was surprised to yet be unable to remove the upper tank. It took some horsing around to remove the upper tank with an upwards movement. A view of the components and fittings explains why the upward movement is necessary. I was surprised that the leveraging motion from the rear of the tank is only applicable to step 1).

Regarding the removal of the trucks, I find that the screws to the trucks are secured by nuts that will simply spin when loosened. Under the each nut is a thin brass washer to which a wire has been soldered. This is capable of winding with the turn of the screw if not managed from the open tender. It may be necessary to remove the circuit board to manage the removal of the rear truck, but access to the front truck is not as yet apparent.

I applaud the engineering of the tender light as there are no wires to frustrate the removal of the upper tank. A plastic light straw conducts the light from the bulb that is seen aimed vertically at the rear of the open tender.

I wish more immediate success to those who subsequently attempt the disassembly of the Bachmann HO Medium Vanderbilt Tender.

-Gary

Close examination of the disassembled components reveal that the upper tank had been GLUED to the chassis where the back of the tank meets the chassis.

For those wishing to follow in my steps, I leave the following guidelines and cautions:

1) I used a hobby knife to gain the release of the stubborn upper tank section. I had initially attempted to pry under the side viewed in the picture, but release did not come until I had pried on the opposite side under the rear and middle sections of the tank. It released with a start causing me concern that the knife may have done damage to the circuit board or wiring (which is possible). Note the lip on the removed upper tank: use care to get the knife under this lip.

2) While loose, several more steps are necessary in order to free the upper tank. The upper handrails need to be separated from the front of the tender. I was able to remove one by hand, but the second one required the use of light needle nose pliers. While holding the upper tank nearly in its original position, it is necessary to back the tank away from the front section in order to free a tongue that secures that connection. I was surprised to yet be unable to remove the upper tank. It took some horsing around to remove the upper tank with an upwards movement. A view of the components and fittings explains why the upward movement is necessary. I was surprised that the leveraging motion from the rear of the tank is only applicable to step 1).

Regarding the removal of the trucks, I find that the screws to the trucks are secured by nuts that will simply spin when loosened. Under the each nut is a thin brass washer to which a wire has been soldered. This is capable of winding with the turn of the screw if not managed from the open tender. It may be necessary to remove the circuit board to manage the removal of the rear truck, but access to the front truck is not as yet apparent.

I applaud the engineering of the tender light as there are no wires to frustrate the removal of the upper tank. A plastic light straw conducts the light from the bulb that is seen aimed vertically at the rear of the open tender.

I wish more immediate success to those who subsequently attempt the disassembly of the Bachmann HO Medium Vanderbilt Tender.

-Gary